Beverley, South Australia

| Beverley Adelaide, South Australia | ||

| ||

| Beverley suburb | ||

| Established | 1849 | |

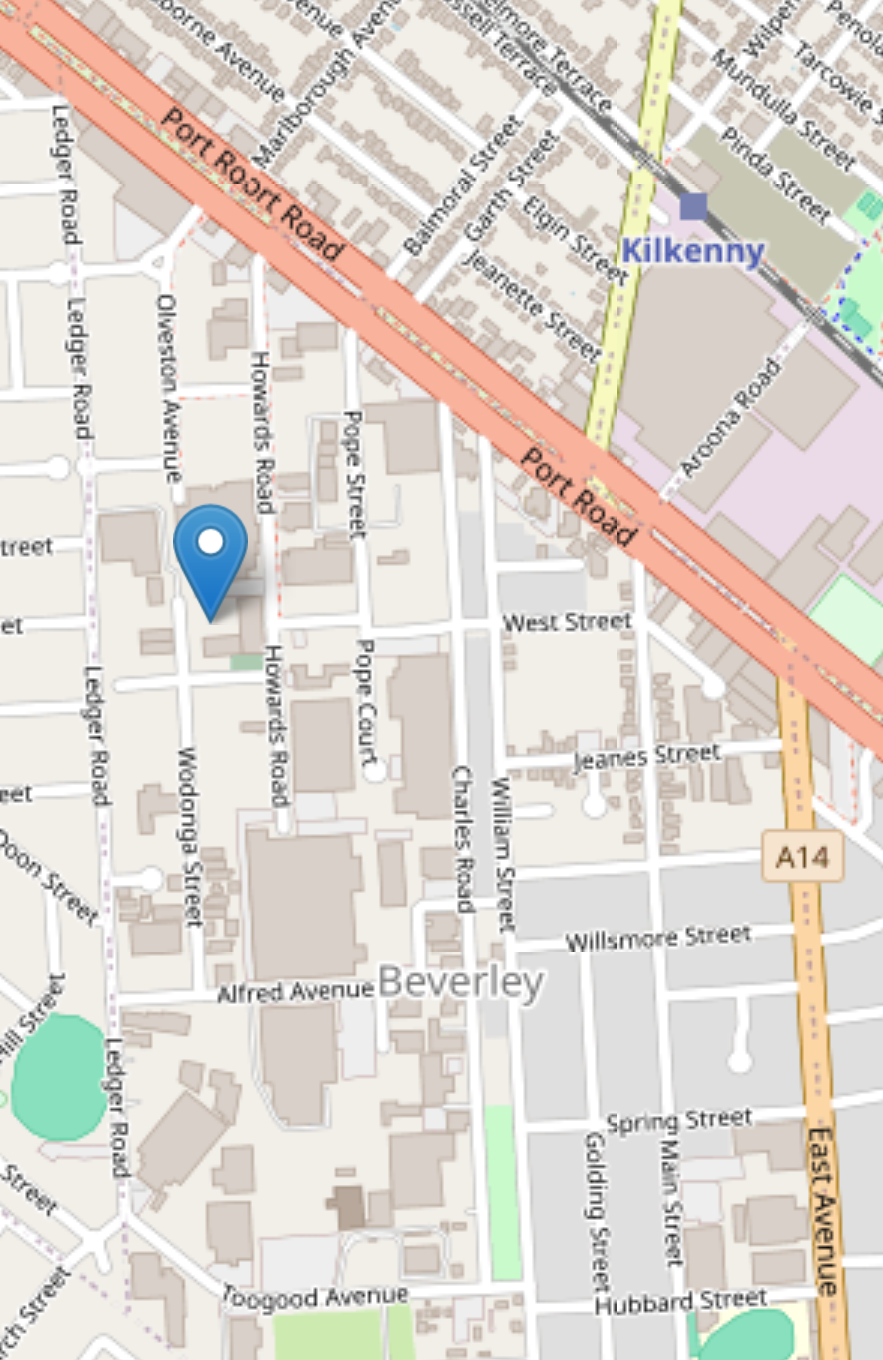

Beverley is a western suburb of Adelaide, South Australia. It is located in the City of Charles Sturt, Bounded by Port Rd, Ledger Rd, Grange Rd and East Rd.

History

The township of Beverley now a suburb of Adelaide was laid out for Edward Stevens by his attorney, John Morphett in 1849 on section 395, Hundred of Yatala,[1] beverley a suburban area north west of Adelaide, is named after Beverley in Yorkshire, England.[2]

Beverley GMH Plant

A report from The Register (Adelaide, 6 August 1927) describes a labour conflict between Holden and engineers at the Beverley factory, according to the article, the Beverley facility was not primarily engaged in motor body construction but rather focused on producing parts essential for such construction, as well as handling all blacksmithing needs for the Woodville shops. Additionally, the engineers at Beverley were responsible for crafting ball sockets and hood frames.[3] When war broke out the Beverley Plant, managed by General Motors-Holden's Limited during World War II, was pivotal in producing anti-tank weaponry. This article outlines the plant's activities chronologically, emphasizing the 2-pdr. Anti-Tank Gun, the 6-pdr. Anti-Tank Gun, and the Polsten 20mm Anti-Aircraft Gun. Before World War II, General Motors-Holden's (GMH) primarily focused on automotive manufacturing. With the onset of the war in 1939, the company quickly transitioned to support the war effort, repurposing its industrial capabilities for military production[4]. As war broke out in September 1939, the Beverley Plant swiftly adapted to its new role. Initial efforts involved retooling and expanding the facility to handle the production of military hardware. This period was marked by intense planning and coordination with government agencies to ensure readiness[5]. According to Susan Marsden, When war broke out in September 1939 the Government purchased outright Holden's small Beverley plant and the Annexe was put to production of anti-tank and anti-aircraft guns,[6]the Beverley plant was responsible for Ordnance and assembled the following equipment for the Australian

Government at the Holden's GMH plant in Beverley, South Australia during WWII, during war time the Beverley plant carried out assembly of artillery guns, these were 2-pdr. Anti-tank guns and carriages, Assembly of 6-pdr. Anti-tank guns and carriages and the Assembly of Polsten 20mm. Anti-aircraft guns and mountings.[7]

Production of the 2-pdr. Anti-Tank Gun (1940-1941)

The Beverley Plant began with the assembly of the 2-pdr. Anti-Tank Gun, a 40mm bore weapon crucial for early war anti-tank operations. The gun was designed to penetrate the armour of enemy tanks, providing essential firepower to Allied forces. In June 1940, three weeks after the events at Dunkirk, a prototype 2-pounder anti-tank gun, constructed in Britain, was transported by passenger train from

.jpeg)

Melbourne to Woodville, South Australia. Although some initial drawings had arrived earlier, with further revisions to the blueprints being made, and additional drawings were finalized, subsequent modifications were implemented, and the gun was completely disassembled to allow subcontractors to inspect various components, they then selected parts they were confident they could reproduce successfully, upon completion, the first batch of produced 2-pounder anti-tank guns was subjected to rigorous testing by military authorities and successfully passed all assessments, this achievement marked a significant success for Australian manufacturing capabilities during that period.[8] By late 1940, the plant had established a steady production line for the 2-pdr. gun, achieving a monthly output rate of approximately 120 units. The development involved creating specialized tooling and machinery to meet high production standards and military specifications.[9].

Transition to the 6-pdr. Anti-Tank Gun (1941-1942)

As enemy armor improved, there was a need for more powerful anti-tank weaponry. The Beverley Plant responded by transitioning to the 6-pdr. Anti-Tank Gun, featuring a 57 mm bore. The plant underwent further expansion and retooling to accommodate the new gun design. This included lengthening existing machine tools and creating new assembly lines. Production of the 6-pdr. gun commenced in early 1942, with the plant achieving rapid output to meet the increasing demands on the battlefield[10].

Production of the Polsten 20mm Anti-Aircraft Gun (1942-1943)

Alongside anti-tank weapons, the Beverley Plant also produced the Polsten 20mm Anti-Aircraft Gun, a versatile weapon used for both anti-aircraft and ground support roles. The Polsten gun was developed as a more manufacturable alternative to the Oerlikon 20mm cannon, with a simplified design. Production began in mid-1942, significantly enhancing the air defense capabilities of the Allied forces[11]. By 1943, the Beverley Plant had reached peak production levels, implementing innovative engineering solutions to overcome material shortages and design challenges. The plant's ability to produce a variety of ordnance efficiently demonstrated the adaptability and ingenuity of its workforce. Special-purpose machine tools and advanced production techniques ensured high precision and quality in weapon manufacturing. Innovations included the design of vertical surface broaching machines and high-pressure coolant pumps, enhancing production capabilities[12].

End of War and Post-War Transition (1944-1945)

As the war ended in 1945, the Beverley Plant began to scale down its wartime production, having significantly contributed to the Allied military efforts. The technologies and skills developed during the war laid the groundwork for post-war industrial growth[13]. When the war was over and in 1946 the Beverley plant was sold to Clarkson Ltd, to one of the old firms in the city, Which then transferred its glass treatment works to Beverley,[14]the Clarkson's owned the property until 1974, at which point it was sold to Arrow Properties Pty Ltd. However, Clarkson continued to lease the property for three years until they vacated it in 1977. After this period, there are few records detailing the occupants and their activities on the site. Presently, Harlaxton Pty Ltd owns the land, which is currently being utilized by ADRAD Pty Ltd.[15]

References

- Manning's Place names of South Australia, Geoffrey.H.Manning, 1990, p.34.

- Place Names of South Australia, By R.Praite & J.C.Tolley, 1970, P.11.

- beverley_history.pdf Environment Protection Authority, Beverley assessment area, Summary of historical activities, 2016, p.20.]

- War Record, General Motors-Holden's Limited, 1945, p.6

- War Record, General Motors-Holden's Limited, 1945, p. 8

- A History of Woodville, By Susan Marsden, 1977, p.215.

- War Record, General Motors Holden's Ltd, Australia, September 1939 - August 1945, p.17.

- War Record, General Motors Holden's Ltd, Australia, September 1939 - August 1945, p.57.

- War Record, General Motors-Holden's Limited, 1945, p. 45

- War Record, General Motors-Holden's Limited, 1945, p. 45

- War Record, General Motors-Holden's Limited, 1945, p.45

- War Record, General Motors-Holden's Limited, 1945, p. 45

- War Record, General Motors-Holden's Limited, 1945, p. 12

- A History of Woodville, By Susan Marsden, 1977, p.215.

- beverley_history.pdf Environment Protection Authority, Beverley assessment area, Summary of historical activities, 2016, p.21.